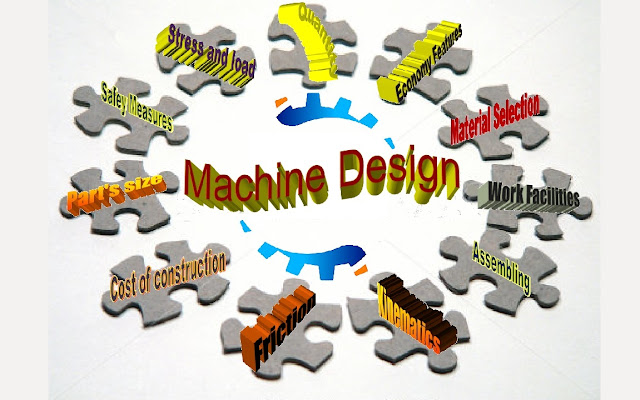

Following are the general considerations in designing a machine component.

Work facilities

Working environment plays a key role to design a machine component. A designer must familiar to workshop and work facilities. It is necessary to plan and supervise the workshop operations and to design method regarding to forging,casting and forming.

Assembling

Every machine consists of components or parts and should be assembled as a unit before it can function. Large units must often be assembled in the workshop and then to be transfer to their servicing place.The final location is very important and the designer must knows the exact location and the local facilities for erection.

Kinematics.

Motion of the parts may be

(i) Rectilinear motion which includes unidirectional and reciprocating.

(ii) Curvilinear motion which includes oscillatory , rotary and simple harmonic.

(iii) constant velocity and constant or variable acceleration.

Successful operations contain simple arrangement of parts which will give the motion.

Friction

There is always loss of power due to frictional resistance and it must not forget that friction of starting is higher than friction at running. To overcome this failure appropriate lubrication is very important. Consider to matter of lubrication of all surfaces which move in contact with others, whether in rotating or sliding.

Cost of construction

Manufacturing a component should be smooth, easy and its overall cost should be minimum. So the cost of construction is very important asset to build or manufacture a component.

Part's Size

Form and size of the part are based on judgement. Either the part is small but it may be checked that the stresses induced in the designed cross-section are reasonably safe. To design any machine component or part for form or size, it is essential to know the forces which the part must sustain. Designer must know the suddenly applied or shock/impact load which may cause the failure.

Safety measures.

Some machines are very dangerous to operate, typically those which are speed ed up to insure production at a maximum rate. So safety measures must be follow to avoid accidents.

Stress and load.

The load, on a machine parts may act in different ways, due to which the internal stresses are set up. These stresses are like compressive,bearing,torsional and bending stressess etc.

Quantity

The number of components or machines to be manufactured affects the design in many ways.

Economy Features.

In designing the operating features of the machine should be carefully studied. The starting,controlling and stopping levers should be located on the basis of convenient handling.Replacement of other parts are should be located in easy mounting positions.

Material Selection

It is important that a designer should have a thorough knowledge of material's properties and their behavior under working conditions. Important features of material are strength, durability and flexibility etc. ( for more read the article in metallurgy)

or click the following link for material properties.

Post a Comment