1: Clamping Devices

If the job or work piece can not be held through locating devices so it is necessary to hold by some other elements, such types of devices are called clamping devices. Bench vice is the most simplest clamping device used in the work shop. The motivation behind the clamping is to apply a weight to press a work piece against the finding surfaces and hold it there in a position to the cutting forces. In bench vice the mobile jaw apply power on the work piece , their by holding it in right position of area in the altered fixed jaw of vice.

Most common clamping devices are used in work shop are as follow.

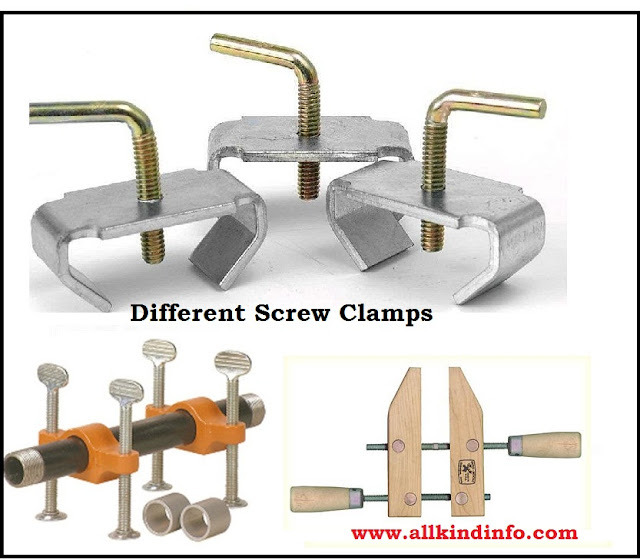

(i) Clamping Screws

Clamping screws are best where small and light work pieces to be clamped.

(ii) Hook Bolts

Hook bolts are also suitable for light purposes and where tip of clamp is inconvenient.

(iii) Bridge Clamp

It is very simple in construction and reliable clamp. The most useful part of this clamp is spring loaded nut..

(iv) Heel Clamp

Heel clamps consists of three major parts, first plate, second center stud and third the heel.This trap ought to be reinforce at the point where the opening for the stud is removed, by expanding the thickness around the hole.

(v) Latch Clamp

Latch clamp is also known as swing strap clamp is very special type of clamp. This clamp is very useful where work piece is to quickly operate to loading and unloading.Lid or latch can easily swing around the job and easy to clamp.

(vi) C-Clamp

It is most useful item used in the workshops.Locking nut is unscrewed by C-shaped. When the clamp is removed the work piece can free easily. The jaw of the clamps fastened the work piece.

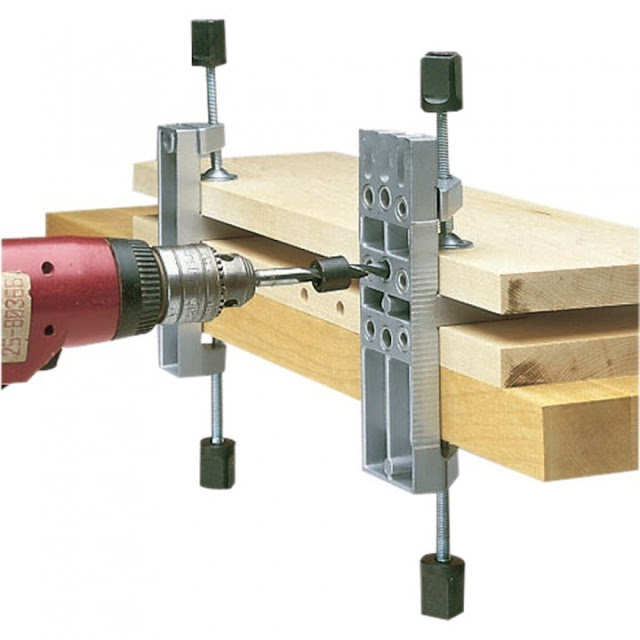

2: Tool Guide or Jig Bushing

Some of the time the firmness of the cutting tool might be in adequate to perform certain machining operations. Then to locate the tool regarding to work piece, use is made of guiding such as jig bushing and templates are used where precision is required.Jig bushed are utilized as a part of penetrating ,boring and drilling,through which the drill passes a bush is used to guide the tool.The diameter of the bush depends on the diameter of the drill.Distinctive sort of bushes are spot welded or screwed with the jig. Headless sort shrubs are press fit into the opening of the work piece. Bushes are general made of a decent grade of steel to protect solidifying at a reasonably no temperature and to lesson the risk of fire cracking. At some point the bushed for managing devices might be of solid metal. Solidified steel bushes are constantly best to guide drills, reamers and taps etc. There are three types of jig bushes according to american standard.

(i) Press fit wearing bushes

These bushes are used where accuarcy dos not matter, such as twist drill is used and press fit bushes are guide the tool. These bushes are mounted directly to the jig body.There are two main types of press fit wearing bushes. (a) head less or plain bushes (b) flanged or headed type bushes

(ii) Renewable wearing bushes

At the point when the guide bushes requires occasional substitution (because of wear of inside diameter of the bush). Its substitution is basically by utilizing a renewable bush. These are of the flanged sorts and sliding fit into the linear bushes, which is installed press fitted into the jig plate. The linear bush gives solidified wear resistance, mating surface to the renewable bush. The renewable bush must be kept prevented from rotating or lifting with the drill.

(iii)Linear wearing bushes

Linear wearing bushes are also know as master bushes which are mounted or fixed permanently to the jig body.These acts as renewable wearing bushes. These are also with or without head shaped.

Post a Comment