Machine Design

The term machine design can be defined as the creations of new and better machines with improving the existing ones. A new and modified machine which is more economical in the overall cost of production and operation.

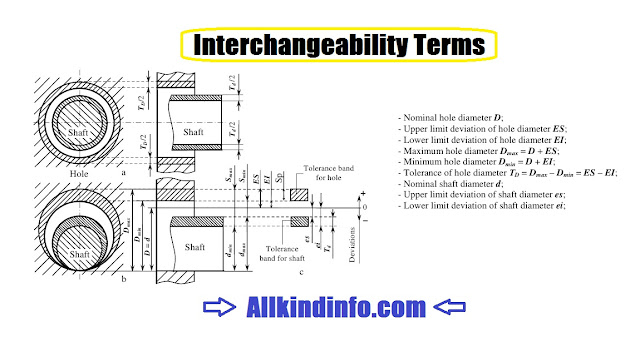

Interchangeability

The interchangeability is normally termed for the mass production of identical items within the prescribed limits of sizes. In order to control the size of the finished product with due allowance for error for interchangeable part is called limit system.

The most important terms used in limit system or interchangeable system are as follows.

1: Nominal Size

It is the size of a part specified in the drawing as a matter of convenience.

2: Basic Size

The size of a part to which all limits of variation are applied to arrive at final dimensioning of the machine parts.

3: Actual Size

It is the actual measured size or dimension of the finished part.

4: Limits of Sizes.

The largest permissible size for a dimension is called upper or high limit and the smallest size or dimension is called lower limit.

5: Allowance

The difference between the basic sizes of the matting parts.

6: Tolerance.

The difference between the upper limit and lower limit of a dimension is called tolerance.Other definition of the tolerance is the permissible variation in a dimension.The tolerance may be unilateral or bilateral.

7: Tolerance Zone

Zone between the maximum and minimum limit size.

8: Zero Line

It is a straight line corresponding to the basic size. The deviation are measured from this line.

9: Upper Deviation

It is the algebraic difference between maximum limit and the basic size.

10: Lower Deviation

It is the algebraic difference between the minimum limit and the basic size.

11: Actual deviation

It is algebraic difference between the actual size and the corresponding basic size.

12: Mean Deviation

It is arithmetical mean between the upper and lower deviation.

13: Fundamental Deviation

It is one of the two deviations which is conversationally chosen to define the position of the tolerance zone in relation to zero line.

Post a Comment