Commonly, the jigs and fixtures devices found in a machine or workshop are for machining operations. Different operations, be that as it may, for example, assembley, layout, testing, and design, are additionally ranges where work holding devices are appropriate. There are numerous varieties inside every broad arrangement, and numerous work holders are really combination of two or a greater amount of the orders.

Common Applications of Jigs and fixtures are as follows.

1: External Surface Machine Applications

Flat-Surface Machining

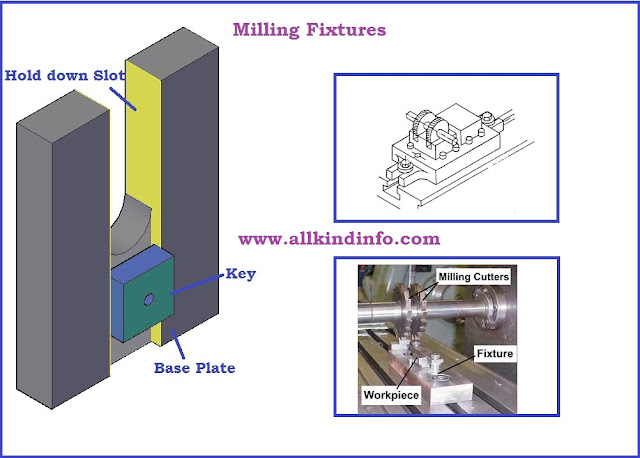

• Milling fixtures

• Surface-grinding fixtures

• Planing fixtures

• Shaping fixtures

Cylindrical-Surface Machining

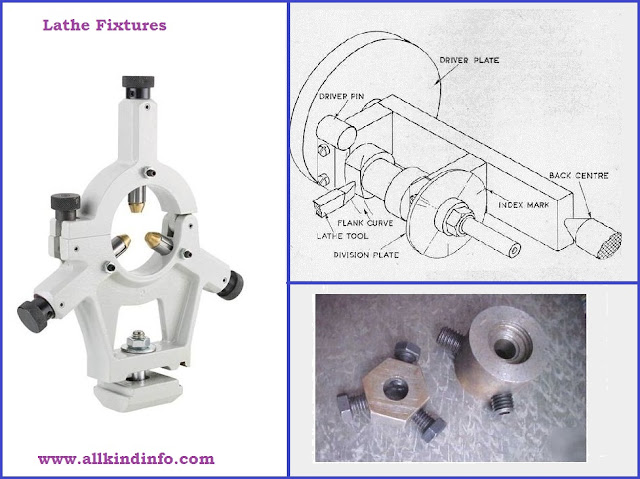

• Lathe fixtures

• Cylindrical-grinding fixtures

Irregular-Surface Machining

• Band-sawing fixtures

• External-broaching fixtures

2: Internal Surface Machine Applications

Cylindrical- and Irregular-Hole Machining

• Drill jigs

• Boring jigs

• Electrical-discharge-machining fixtures

• Punching fixtures

• Internal-broaching fixtures

3: Non Machining Application Assembley

• Welding fixtures

• Mechanical-assembly fixtures

(Riveting, stapling, stitching, pinning, etc.)

• Soldering fixtures

4: Inspection

• Mechanical-inspection fixtures

• Optical-inspection fixtures

• Electronic-inspection fixtures

5: Finishing

• Painting fixtures

• Plating fixtures

• Polishing fixtures

• Lapping fixtures

• Honing fixtures

6: Miscellaneous

• Layout templates

• Testing fixtures

• Heat-treating fixtures

7: Modular Fixtures

Modular fixtures accomplish a considerable lot of the benefits of a changeless device utilizing just a temporary setup.Modular work holding join thoughts and components of both lasting and temporary work holding to make reasonable yet-solid work holders.The essential point of interest of modular fixtures is that an apparatus with the advantages of lasting tooling (setup reduction, toughness, profitability upgrades, and precision) can be worked from an arrangement of standard segments.

Post a Comment