Despite the fact that forging process give by a large superior quality item thought compared other manufacturing processes. There are a few absconds that are gently to come a legitimate consideration is not taken in forging process plan.

A brief depiction of such abandons and their remedial method is given underneath.

1 : Unfilled Sections

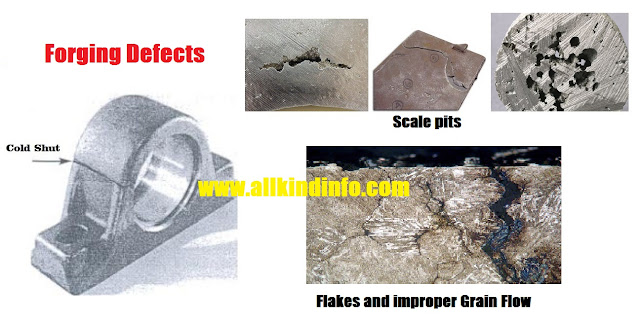

Most of the cases in die cavity the flowing metal does not fill the whole component and causes the unfilled sections. Reason of this defect is lack of in proper forging skills and design combination of forging die.2: Flakes

These are fundamentally inner cracks brought on by the improper cooling of the huge forging. Fast cooling causes the outside to cool rapidly bringing on inward cracks. This can be cured by taking after legitimate cooling techniques.3: Cold Shut

When small appears at the corners of the forging, is termed as cold shut. It is also becomes due to the design error of the forging die.

4: Scale Pits

This is seen as irregular ruptures on the surface of the forging. This is primarily caused because of improper cleaning of the stock used for forging. The oxide and scale gets embedded into the finish forging surface.

5: Die shift

This defect of forging appears when die halve is misaligned, creating the improper shape of the forging component.

6 : Improper Grain Flow

This is also error design in the die, which casuses the flow of metal improper grain stucture of the forging.

Post a Comment