Common forging operation are follows.

1: Drawing.

This is the operation in which metal gets stretched with a reduction in the cross sedation zone. For this, a power is to be connected in a course perpendicular to the length axis.

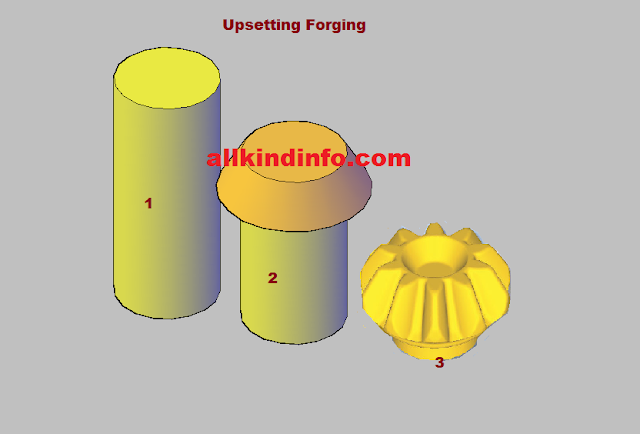

2 : Up setting

This is connected to build the cross sectional area of the stock at the expanse of the length. To accomplish the length of annoying power is connected in a course parallel to the length axis, For example shaping of a bolt head.

3: Fullering

It a like to material cross-area is minimized and length expanded. To do this; the base fuller is kept in point gap with the warmed stock over the fuller ,the top fuller is then kept over the stock and afterward with the sledge hammer, and the power is connected on the top fuller.

4: Bending

Bending is exceptionally regular producing operation. It is an operation to give a swing to metal bar or plate. This is required for those which have bends shapes.

5: Edging

It is a procedure in which the metal piece is dislodged to the desired shape by striking between two passes on edging is as often as possible as essential drop forging operation.

6: Forged welding

It is a procedure of joining two metal pieces to expand the length. By the squeezing or hammering then when they are at forging temperature.It is performed in blacksmith shop and consequently is called forged welding.

7: Cutting

When two pieces of metal rods or plates splits, the process is called cutting.It is done when the material is red hot and it is done by the help of chisel and hammer.

8: Punching

It is a procedure of creating gaps in motel plate is set over the empty round and hollow pass on. By squeezing the punch over the plate the opening is made.

9: Swagging

is done to diminish and complete work for craving size and shape, typically either round or hexagonal. For little jobs top and base swag pair is utilized, where with respect to vast work swag piece can be utilized.

10: flating and setting down

Fullering leaves a ridged surface at work. Indeed, even after a job is forged into shape with a hammer, the signs of the sledge stays on the upper surface of the work piece. To remove hammer imprints and layering and keeping in mind the end goal to get a smooth surface at work, a compliment or set hammer is utilized.

Post a Comment